International Study Seminar – Day 2

Monday, March 10, 2014

– written by Tadgh Davis, Nick Nagele, & Jared Nobbe – Presiding Fellows

Wow! What a great first full day in Germany! A welcome full night’s sleep to cure jet lag had us ready to start our day at the Cargill Grain and Oilseed facility in Mainz. During our bus ride there, we discussed the changes in our destination and why we find ourselves in Germany rather than Ukraine and Russia. We had an interesting discussion led by Ron Warfield on the controversy involving the Russian occupation of the Crimea area in Ukraine. Varying perspectives on this issue were shared by class members but all were in agreement that Russia is indeed illegally occupying Crimea and they have no intention of leaving because of the very valuable warm water port.

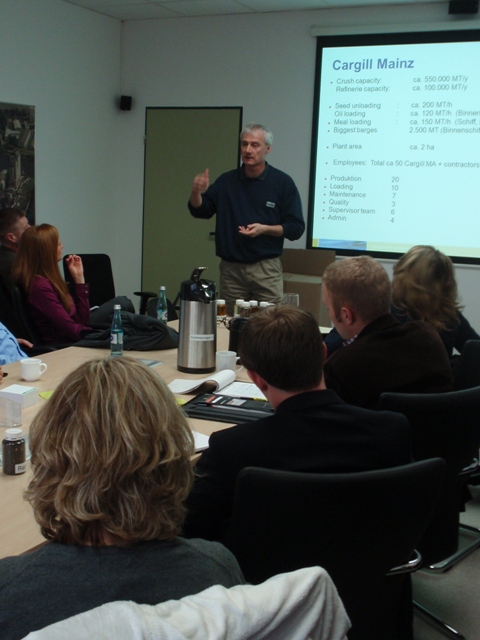

At Cargill, Dr.Thomas Rau gave us a very in depth presentation on Cargill, and the Rapeseed (Canola) crush and refinery plant. We learned that sixty percent of the oil made at the plant goes into bio fuel with the remainder refined into vegetable oil. The meal produced at the plant is used for animal feed. One of the interesting things that Thomas mentioned was that the taxes on electricity in Germany – used to finance clean energy subsidies -are higher than the actual cost of electricity! He also mentioned that all of their feedstock is non-GMO due to strong public anti GMO sentiment- something that he believes is based on emotion and not science. Both of these issues are examples of why we in the agricultural industry must proactively tell the fact based story. The unsustainable subsidy program for clean energy in Germany is not all that different from what environmentalist groups in the US are pushing for. The non-GMO feedstock is also an agenda items that activist groups back home would like to see – and that we need to fight against.

We then travelled to Heidelberg to tour the CNH Parts Depot. This is a massive warehouse and impressive display of logistics. Last year 1.9 million SKU’s were shipped out. Safety is a priority with automatic sensors and alarms engaging if a person enters an aisle with a forklift present. One of the most interesting aspects of the depot was strong commitment to customer support. The parts depot is able to take an order for a part and deliver that part to their dealer within 5 hours. The impressive logistics and extraordinary customer support display German innovation at its finest.

Volker Hauf of the CNH Parts Depot Heidelberg showcases their efficient methods of serving customers across Europe.

Comments are closed